Beolife: a speaker for the environment

Context: Bang & Olufsen Innovation Camp in Struer, Denmark

Team: Hayo Vaatstra, Igor Gierałt, Liangyi Du, Marta Latocha, Rooske van Loon, Martyna Konopka

Inspiration: Visits to the factories revealed a need for a more sustainable approach within the company

Outcome: A concept of a flat-pack speaker made of sheet metal to reduce production processes and shipping needs

A collaboration of students from different backgrounds to create an original speaker concept

As a team of 6 students from The Netherlands, Poland, and China, we faced the up-and-down challenges of the creative process to settle on designing a sustainable solution, never before seen in existing Bang & Olufsen products.

During production, tonnes of elements are rejected and turned into scrap due to minor defects or imperfections

Before starting the design process, we were taken on a tour of Bang & Olufsen’s production facilities. During a visit to the factory, we were able to see the processes of forming metal and plastic, as well as product assembly. This gave us a good idea of the different affordances throughout production, but also revealed the vast amount of material that has to be scrapped because of an imperfect finish or minuscule scratches in order to achieve the highest quality in each product.

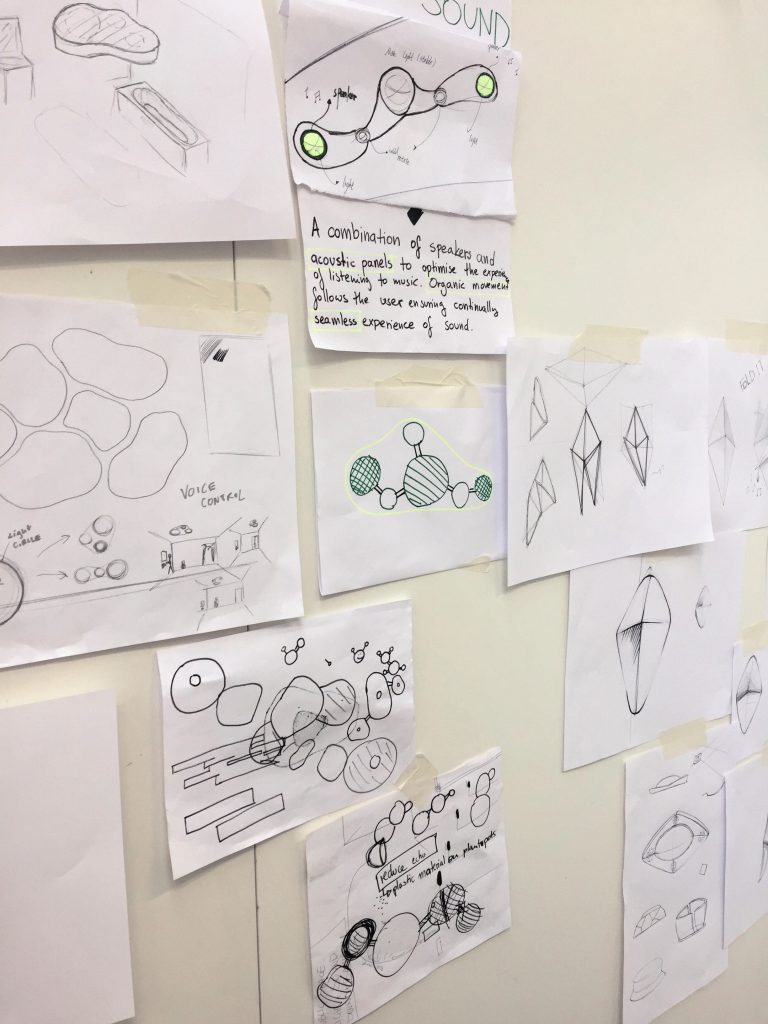

Talks from sound engineers and design specialists helped us think about sounds and conceptualise the surrounding physics.

We began the ideation process with a Value Proposition Model to define a problem area to focus on. Moving on to various creativity techniques such as De Bono’s hats and automatic drawing, we generated ideas and tested them with prototypes. Despite reaching multiple dead ends (organically-moving speaker for the bathroom ceiling?), we eventually experienced a eureka moment after going back to the drawing board and exploring simple geometry.

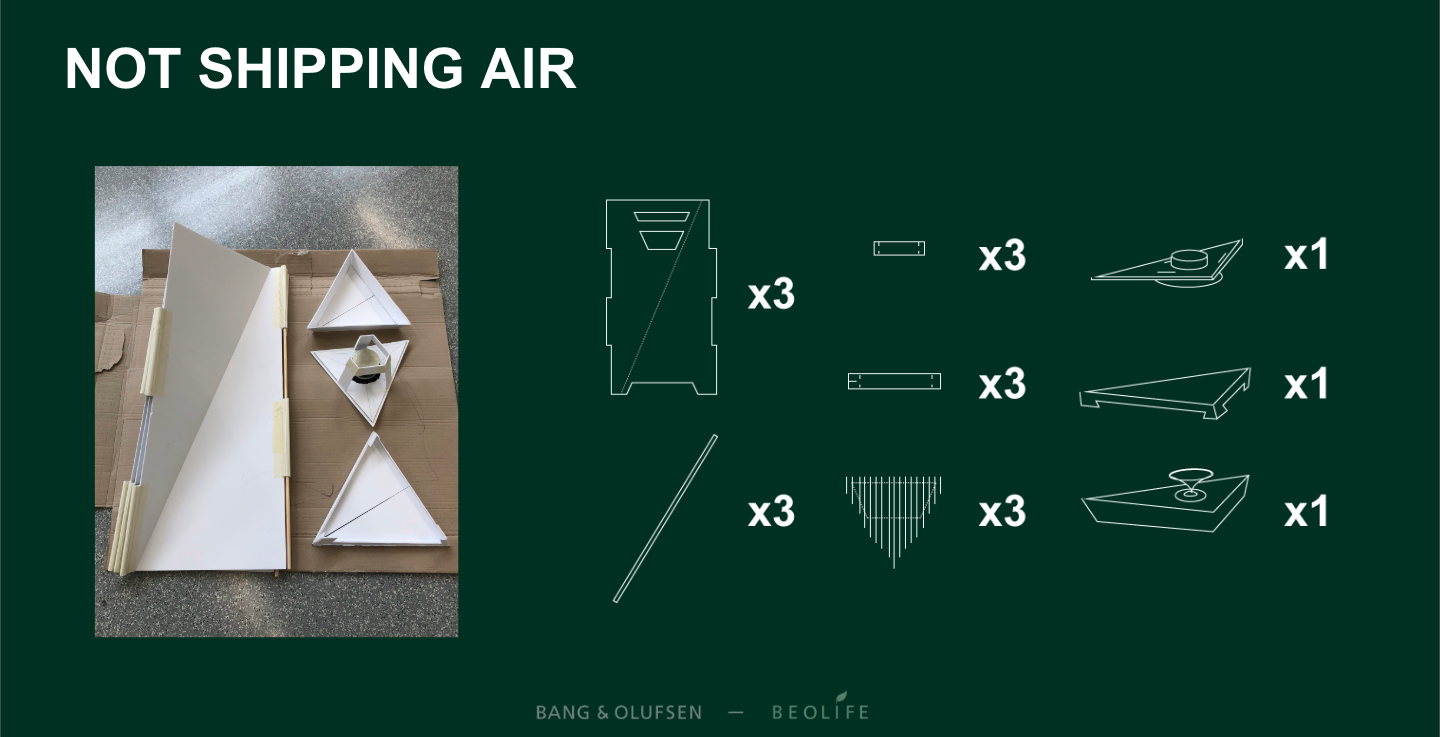

A flat-packed speaker to minimise space, and reduce both shipping costs and emissions

Packaged into a box the size of one-third of the final product volume, the Beolife reduces shipping costs, emissions, and packaging material, making it the first potential sustainable solution for the brand.

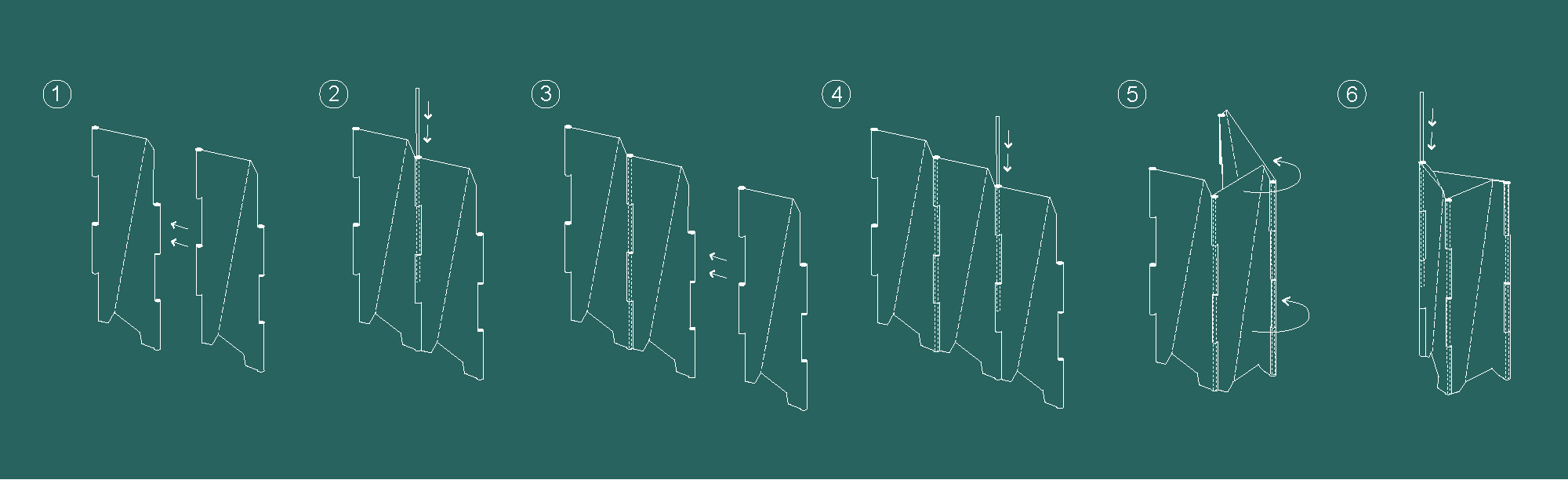

The body of the speaker is made of three identical sheets of aluminium connected by cylindrical rods at their three edges of contact. The sheet aluminium is laser cut and bent into a simple shape which is stackable when disassembled. The three drivers (tweeter, mid range, and woofer) are shipped as separate units, ready to be fitted into frames within the body.